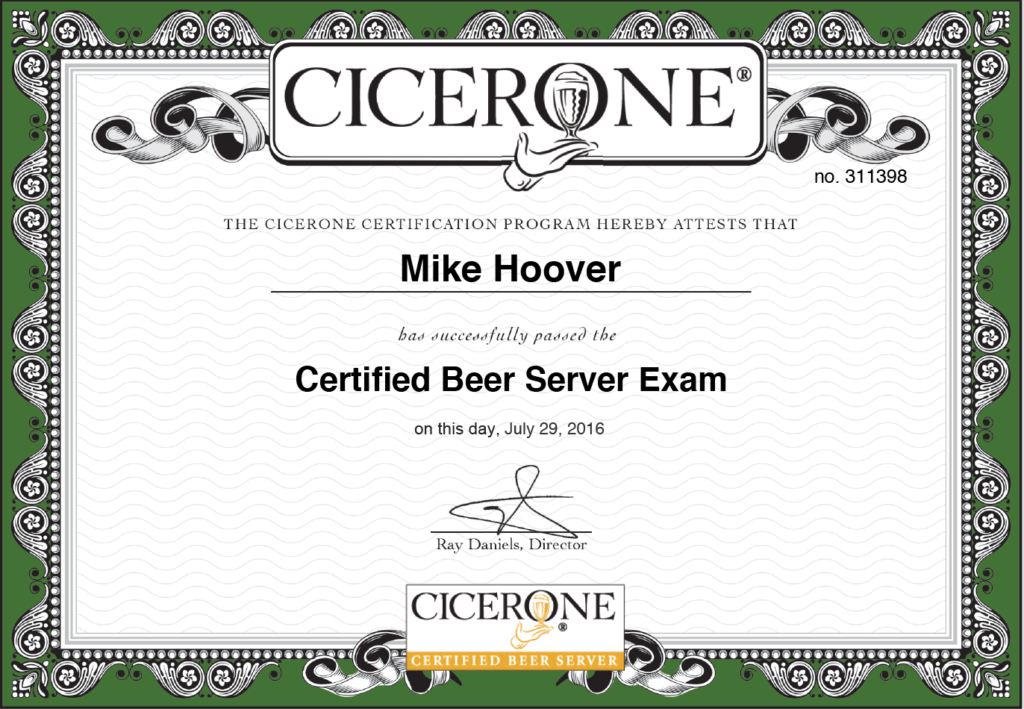

I achieved the first level at Cicerone.org – Certified Beer Server on July 29, 2016. I studied their BeerSavvy program beforehand and it was well worth the investment.

Please follow & like us :)

-

Recent Posts

Recent Comments

Categories

Archives

- June 2025

- July 2022

- July 2020

- November 2019

- August 2019

- June 2019

- March 2019

- January 2019

- November 2018

- October 2018

- September 2018

- August 2018

- July 2018

- June 2018

- May 2018

- March 2018

- February 2018

- January 2018

- December 2017

- November 2017

- October 2017

- September 2017

- August 2016

- March 2016

- November 2014

- October 2014

- January 2011

- December 2010

- November 2010

- October 2010

Meta