Made another batch of soap yesterday. This time I used coconut oil sourced from Sams Club. It is Member’s Mark brand. The label says “Organic Virgin Coconut Oil Cold Pressed & Unrefined”.

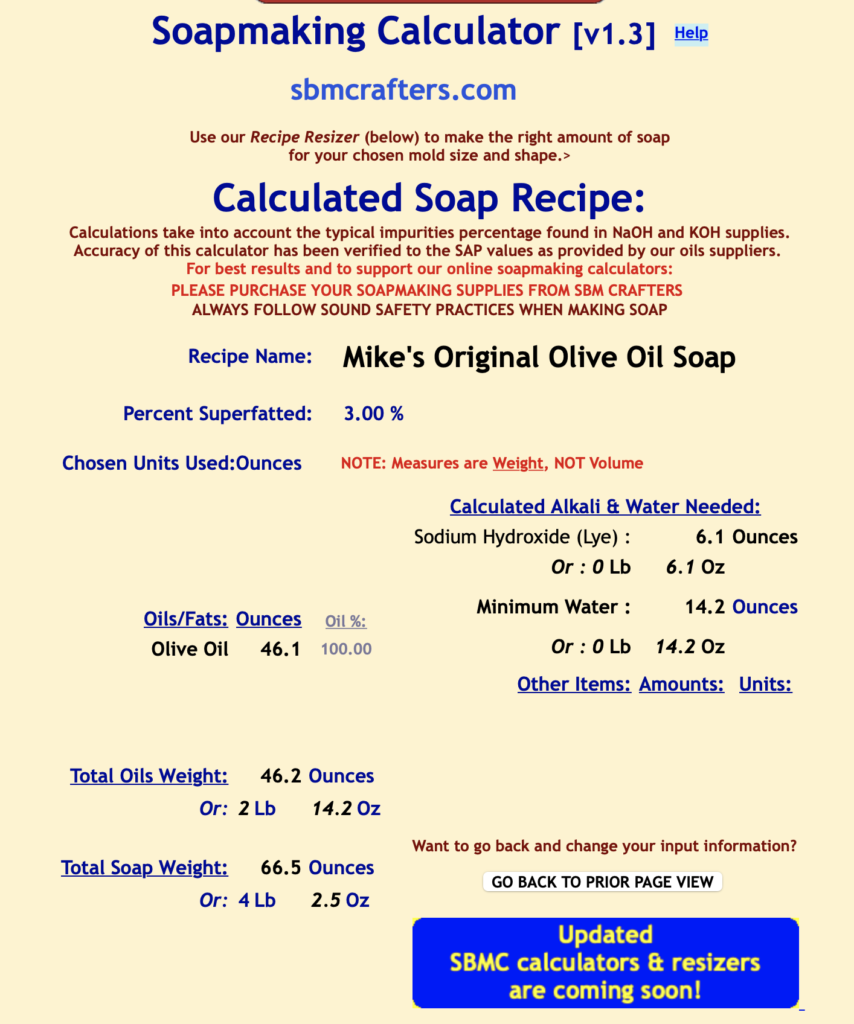

The old online soap calculator I used to use is now defunct so I searched for another one. Found one that looked straight forward at LyeCalc.com. I used the beginners version. Pretty simple.

The container of coconut oil is 56 fluid ounces. It weighed in at 1665 grams. I pour all the coconut oil in a pot and weighed the empty container. It weighed 150 grams. That gave me an oil weight of 1515 grams. I used the default 5% superfat, but changed the water percentage to 30%. The default is 38%. The calculator said to use 454.5 grams water ( I used distilled water), and 264.82 grams of NaOH (sodium hydroxide granules).

I donned my rubber gloves and safety goggles and went to work outside on the deck. I weighed out the distilled water in a measuring cup and added the NaOH to that and stirred well. After a minute or two I measure the temperature of the solution. It was 208ºF! I let it sit and heated the oil up to about 140 to get it all melted. I let them both cool down for a good while. The lye solution was at 118ºF and the oil was at 121ºF so I began to mix them. I slowly poured the lye solution into the oil while mixing slowly. Start time: 2:42 pm. After mixing with the hand mixer in short bursts and stirring with it for what seemed like forever. I started wondering if I would ever see trace.

The soap finally traced at 3:16 pm and went fast. I poured it into the mold. It thickened up quickly. I used the spatula to smooth it out as best I could. The mold was very hot. It was cooking! I covered it with a piece of cardboard and a towel. It stayed warm for many hours.

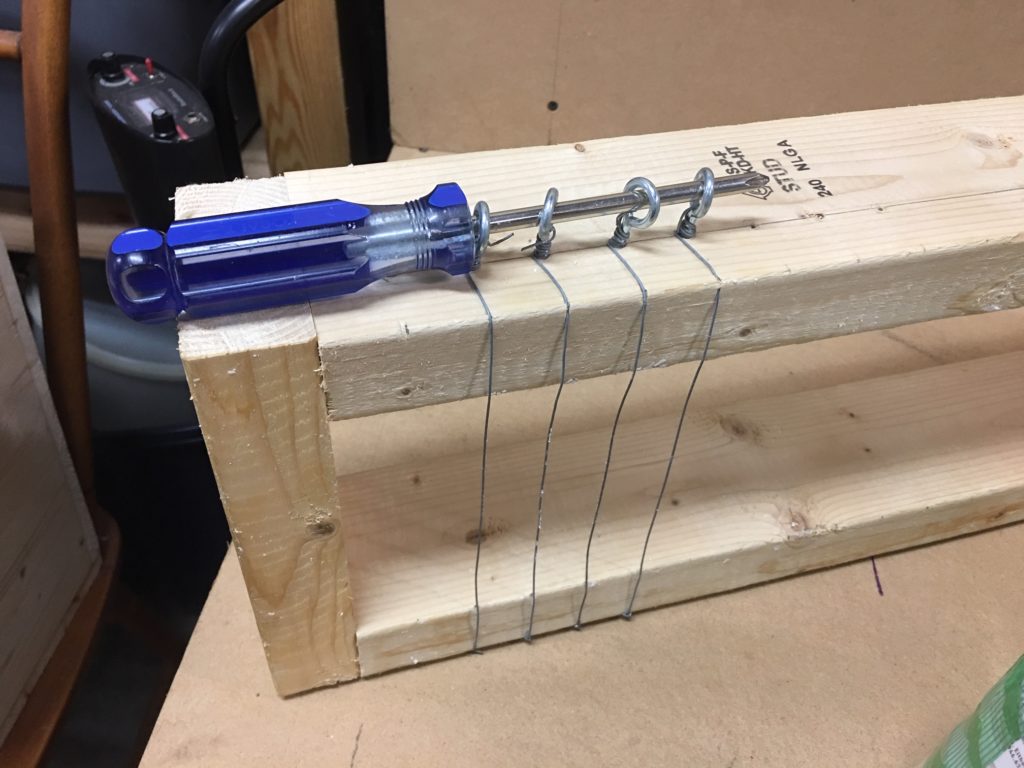

The soap hardened up pretty quickly. At 10am the next morning, it was hard. I was concerned I would not be able to cut it so I went ahead and de-molded it. It was too hard to use my wire soap cutter (my homemade rough version of one) so I used a kitchen knife. It cut pretty well. I ended up with the expected 18 bars. I trimmed them up and placed them in a container and covered with a cloth.

The soap turned out pure white and has little smell to it, maybe a slight toasted coconut aroma. I tried washing my hands with a bar. It lathered up nicely!

Found an extensive SAP table at fromnaturewithlove.com. Also, good information about recipes at brambleberry.com. Also, SoapCalc.net is a popular calculator.

Turns out that the calculations for ingredients are not that difficult. Start with the weight of the oil you are using, multiply that by the SAP number for that particular oil to get the weight of NaOH required. Reduce the NaOH weight by the percentage of superfat you desire, ie, 5% superfat, multiply the NaOH calculated by 0.95 to arrive at the new NaOH weight. The distilled water is typically 30-38% of the weight of the oil.

My recipe: 1515 g coconut oil x 0.184 = 278.76 grams of NaOH. Superfat at 5%, so 278.76 x 0.95 = 264.82 grams NaOH required. For the water at 30%, 1515 grams oil x 0.30 = 454.5 grams distilled water required.